3 April 2020

Finding a consensus view on the Luming Mine tailings accident

Posted by Dave Petley

Finding a consensus view on the Luming Mine tailings accident

Many thanks to all of you who have contacted me about the Luming Mine tailings accident over the last few days, and for the comments about the accident posted to this site too (I’m not sure why some of the comments are not showing – this appears to be a glitch with WordPress). I appreciate the hard work that many of you have put into this problem.

I thought it would be useful to summarise the consensus view of the accident, which makes use of the amazing knowledge that lies in the wider community. I shall make reference to the Planet Labs image again:-

Planet Labs SkySat image of the aftermath of the Luming Mine accident. Image collected by, and copyright of, Planet Labs on 1 April 2020.

.

The strong consensus is that the origin of the Luning Mine tailings accident is the depression that has formed in the centre east side the above image. The tension cracks and the formation of a new erosional gully in this area indicate that there has been a substantial loss of material. Some have suggested that there might have been flow over the southern abutment of the southern starter dam. I have also wondered about this, but I think the similarity of that area to the northern abutment of the northern starter dam makes this unlikely. I would welcome thoughts.

There is an image of the depression online on another Chinese news website – it describes this area as “No. 4 overflow shaft”.

The discharge of the tailings appears to be the area of the blue hut just to west of the foot of the abutment of the southern starter dam, which line us with the failure point in the tailings pond. After a trawl of Chinese news websites I found the following image, which was posted to a website called fjsuchi. I don’t know much about this image as my PC will not allow me to access the site itself due to a security warning, and so I won’t post a link. But it appears to show the likely discharge point of the tailings and polluted water at the foot of the dam:-

The possible discharge point for the Luming Mine tailings accident. Image from fjsuchi.

.

That then raises the question of what was happening at the point of failure in the tailings pond. Two hypotheses have been proposed in the comments. One is that this was a decant tower, a structure constructed to dewater the tailings. In a good primer on tailings facilities construction it is noted that:-

Inadequate decant design has caused major dam failures. Many older dams used decant towers with discharge lines running through the base of the dam to a downstream pump-house. Failures of such structures were common due to the high pressures exerted on the pipelines, leading to uncontrolled losses of fluids and tailings downstream.

If this was indeed a decant facility then could it be argued that this relatively new tailings facility is using out of date technology? That might be reinforced by the fact that the tailings dam approach to construction is clearly the upstream method.

The alternative possibility is that this is a reclaim system. In this case the water is extracted from the tailings and reused in the mill rather than being discharged into the river.

The Google Earth image of the failure area, taken in 2018, shows a structure:-

Google Earth image from May 2018 of the structure at the site of the Luming Mine tailings accident.

.

I invite those with expertise to comment on what this structure might be. In his comment yesterday, James Turner notes that:-

You can use Google Earth Pro Windows’ satellite image history you can follow the starter dam construction as well as the standpipe boring.

If you place pins at drill site pads in several locations they track standpipe discharge points in later photo at the shoreline, opposite the portal outlet by the blue pump station. Start with the Aug and Oct 2013 images and there are a chain of drill sites working back East where the pond shore would later be. In one image you can see a drill frame. A Sept 28 2015 image shows standpipe locations along the now flooded shore. One of the standpipes that was at the shore but later drowned seems to be the leak source.

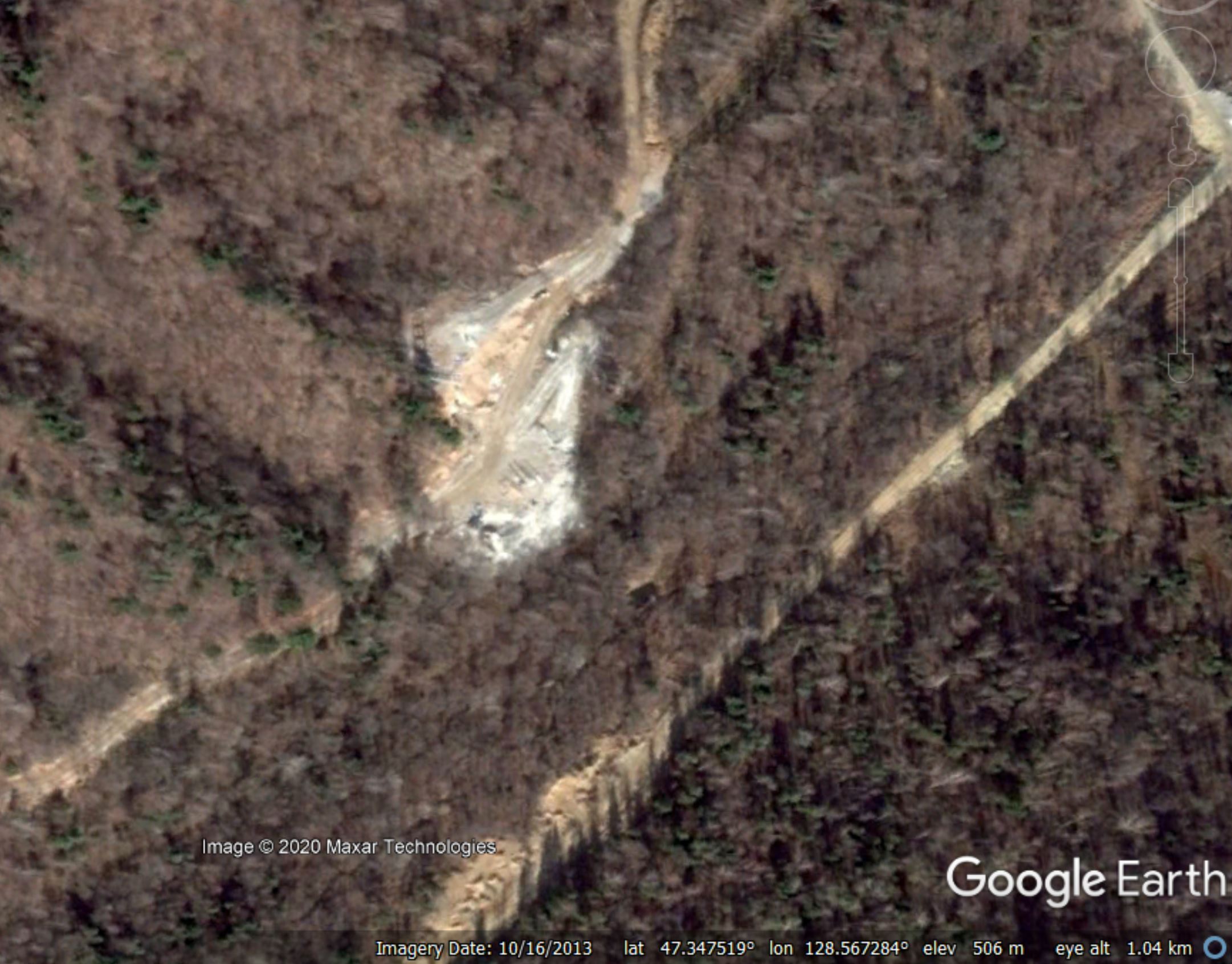

Take a look – the location is 47.346, 128.569. The key might be this Google Earth image from October 2013:-

Google Earth image from October 2013 of the structure at the site of the Luming Mine tailings accident.

.

This is the same site as in the previous image. There was clearly site preparation work at this location.

So, the question to those of you with expertise in this area (and there are many of you), what does the evidence from the apparent discharge point in the second image in this post, the structure in the third image and the site preparation in the fourth image indicate was happening at this site prior to failure?

And, of course, what does this tell us about the quality of tailings management leading up to the Luming Mine tailings accident?

Over to you.

Reference and acknowledgement

Planet Team (2020). Planet Application Program Interface: In Space for Life on Earth. San Francisco, CA. https://www.planet.com/

Thanks to all of you for your fantastic insight to this problem. It reminds me of the way that we solved the mystery of the 2012 Seti River rock avalanche in Nepal.

Dave Petley is the Vice-Chancellor of the University of Hull in the United Kingdom. His blog provides commentary and analysis of landslide events occurring worldwide, including the landslides themselves, latest research, and conferences and meetings.

Dave Petley is the Vice-Chancellor of the University of Hull in the United Kingdom. His blog provides commentary and analysis of landslide events occurring worldwide, including the landslides themselves, latest research, and conferences and meetings.

To me, it’s clearly a decant tower failure. Google earth has good imagery of the construction of these decant towers (see the one at 47.344958°, 128.564205°, using the timetravel tool). I suppose they seal them afterward.

Reading back your post from 1st April, I understand that after the failure, they had to make a new road to reach the decant tower n°4 who failed (the previous one was bad because of winter conditions), and seal it with rocks, sand and cement, but when the failure occured, the icy part of the water surface has buried and hidden the tower. They had to de-ice the site and then fill sealing material in it.

As usual thanks for your time operating this blog (sorry if my english is not that good…).

[Thanks for your kind words, this blog is a genuine pleasure. Your observations are really useful. Other thoughts? D.]

Well, i am wondering what led to the failure… is it a strucural design problem? maybe winter conditions here could be part of the problem…? I don’t know exactly how a decant tower works, but I assume there would be some sort of drainage holes around the tower, possibly frozen ? could it lead to a higher pressure on the structure which then collapse ? or maybe the lower holes sealed during the uprise of the sediments failed? Saying that because of the image found at page 42 (or 44) of that document : https://docplayer.net/62530041-Report-tailings-management-facilities-intervention-actions-for-risk-reduction.html

It is perhaps important to note that this does not seem to be a tailings DAM failure. There is no sign of large seepage into the secondary ponds below either of the main dams. Rather, some thing has gone awry with the reclaim system. Here in BC on the larger copper mines a floating barge is used on the reclaim pond to pump water back to the mill for reuse in the ore process. Photo #3 shows what looks like the reclaim pond, possibly with a fixed pump on the shoreline.There should then be a pipeline leading back to the mill.

We don’t know anything about the weather conditions at the time of the discharge. But if an overflow decant tower did lead back to the outlet in photo #2 it may have been overwhelmed leading to discharge of water and slimes downstream, perhaps with little or no actual structural failure. Anyway, there is another hypothesis.

I believe the original Chinese interview stated that ice damaged the tower leading to the leak.

Not a dam failure, but definitely a decant system failure. I’ve been using the term standpipe since the Chinese translation called it that but it’s really a decant system with the decant towers being translated as ‘standpipes’. And we now have further confirmation with Prof. Petley’s latest image that the presumed portal is indeed the outflow for the leak.

This decant system is bored into underlying bedrock rather than laid under the dam as no historical photos show pipeline trench construction between the original drill sites and the portal by the dam toe. If you look at Google Earth Pro historic satellite imagery in 3D the terrain becomes more obvious for the drilling into bedrock. All of this is free to anyone to view.

They have a reclaim barge (red roof to the farthest east) in more recent sat images, so I presume the decant system was to retrieve reclaim water when there was a shallow pond with a lot of suspended fines/slimes and a quickly progressing beach front.

The blue roof building by the collection sump is likely a pumping station for a reclaim line back to the mill. Its also collecting seepage from that nearby dam via a ditch and combining the two for reclaim (which you can see in historic images). There has to be a buried reclaim pipeline because there is no outflow from the sump despite the high flow visible by the white water turbulence in the sump by the portal, and the toe seepage. But I can’t find historic images to confirm a pipeline, it can only be presumed.

Recent Google Maps image of the presumed sump and reclaim pumphouse. Compare the rock/brick retaining wall in the image of the muddy portal above with the rock/brick wall behind the portal in the sat image, its the same portal and retaining wall: https://goo.gl/maps/SDacFxinjeUtX3yY7

Bing Maps image of construction of portal, sump and pumphouse: https://www.bing.com/maps?osid=9e2bbd8b-9dd0-4767-95e5-9a2a7e80e903&cp=47.342141~128.555556&lvl=19&style=h&imgid=6edb4388-2d5d-434b-8733-8deeb2e644a2&v=2&sV=2&form=S00027

Hi, Dave and all!

Thanks for amazing teamwork!!!. Myself and a couple of Russian ecologists have been digging into that accident from the other end. Let us together try to explore possible CONSEQUENCES of this specific accident.

Reason we are worried – past experience with toxic spills in Amur-Heilong river basin. I still remember the panic of 2005 when a chemical plant basted in Jilin threatening by toxic spill Harbin and Habarovsk cities and dozens of smaller settlements downstream on Songhua and Amur rivers.

First, all Chinese sources say about 2 500 000 cubic meters of released substance (estimate never changes from first report on March 30th till yesterday). On one hand I wonder whether it is really possible to estimate the volume, on the other hand, not being an engineer, I am amazed by such a huge volume to be lost through a pipe with dam staying intact.

Second, Chinese Ministry of Environment everyday reports only on three pollutants : molybdenum, oil and COD. Meanwhile there is much broader range of possible pollutants: “… sodium sulfide or sodium cyanide will be used as flotation agents in the beneficiation process, and kerosene, sodium silicate or pine root oil will be used as auxiliary agents, resulting in the discharge of waste water containing drug residues, which is hazardous. According to the September 2019 environmental testing report of Luming Mining, its industrial sewage and solid waste include various heavy metals including lead, zinc, arsenic, chromium, mercury, and cadmium.” (googletranslated) https://www.hugage.com/huanke/2020-04-01/1780.html(strongly recommend to look though this source). Above and beyond that they use a range of substances for flocculation(?)-I mean provoking reactions to remove metals from the water.

Third, your imagery shows that sludge poured through nearby village affecting 35 out of 40 households\landplots…(do I understand the image correctly? DAVE – I seek your permission to show that picture on http://www.transrivers.org) I have not found any source mentioning impacts on villagers. Many reports say that water supply for downstream town of Tieli was rearranged due to contamination of Yijimi River.

So, we are trying to understand possible environmental consequences of this contamination, likelihood it will affect larger rivers downstream (Hulan, Songhua, Amur) and efforts the company and authorities could undertake to minimize damage before next flood season. My blog from yesterday is here in Russian https://www.sibreal.org/a/30527881.html. Any ideas a very welcome!!

Besides You maybe interested to read this analysis https://earthworks.org/blog/china-sees-2020s-first-tailings-spill/

Finally I independently arrived yesterday at observation about increase of accidents in times of decreasing metal prices and prospects of bailout by government. Molybdenum price is in sharp decline and as recent as March 25 Luming Co. was lamenting about it in sectoral review along with many other producers. Collectively they expected partial relief due to closure\bancrupcy of several similar producers around the world. Do I correctly assume that this accident may make Luming Co. slow down production for a while and thus further situation of relieve other producers?

Cheers

Eugene Simonov

Rivers without Boundaries

If you examine other parts of the Bing imagery referenced by Turner, there is cylindrical outlet cage / trash-rack structure under construction at the location of failed No. 4, and a second apparently completed one around halfway between it and the blue-roofed downstream outlet structure. I also note an apparent vertical shaft to the NNE of #4, and large staging area SE of there w/ what appears to be a horizontal adit aimed at the shaft. Perhaps a breather pipe for a future horizontal tunnel?

Here is my theory as a non-dam person: as mine tailings accumulate around the inlet structure, they install permeable baffles on the cage to bring the inlet level back up and keep relatively clear surface effluent entering the standpipe. Effluent continues filtering thru the sides of the cage. This continues as needed until the max containment height is reached.

My money is on a structural failure of either baffles and/or the cage itself (because it’s not visible in the latest photos and we understand they’re trying to dig down to it). Sudden collapse could have led to strain-induced liquefaction of the surrounding slurry which then blasted out of the outlet as seen, like water exiting a bath tub, creating the observed crater. Floating slabs of ice may have blocked the inlet temporarily, in which case, there may be another outburst in the spring if they can’t resolve the issue,

PS: I also note two other “standpipe cages” on the other side of the ridge in Turner’s Bing image, one of which corresponds to the structure visible on the recent photos. The other two (west) closer to the outlet building have been entombed and sealed.

I note a broad apron of dark slurry around the structure across the ridge from #4 in the recent photos, which could be the result of effluent from #4 punching straight across/under the ridge in a connecting tunnel, then burping up and out of it onto the adjacent surface as the effluent wave blasted thru the system, finally making its way to the outlet portal via shared connecting tunnel. I’m betting these inlets were tied together in the shape of a telephone pole lying on the ground with inlets sharing common tunnels on opposite sides of the ridge like the crossbars on the pole, and the pole itself as the common tunnel connecting them,