27 April 2011

Pond scum a viable alternative to imported oil

Posted by Michael McFadden

Instability in many of the world’s largest oil producing nations has gas prices on the rise and policy makers again considering alternatives. But biofuels, which were once heralded as a way to wean the country off of imported foreign oil, also come with their own disadvantages.

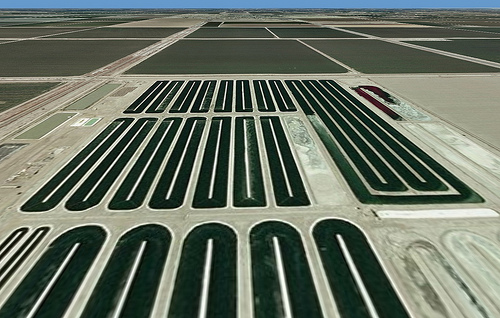

Recently, fuels made from algae have gotten increased attention, but they can require enormous supplies of water to produce and it’s remained a mystery how much fuel could realistically be generated this way. In a study unveiled earlier this month, researchers have determined that if the United States dedicated every suitable acre to producing fuel from algae, the nation could generate an amount equivalent to nearly half its annual petroleum imports for transportation.

But, such massive production of algae biofuel, which would be made by growing the microscopic water plants in outdoor ponds, would consume nearly three times as much fresh water as is used today nationwide for agricultural irrigation: That’s 1,421 liters (about 375 gallons) of water for every liter (or 0.26 gallon) of fuel created, the researchers report.

A more realistic scenario also investigated in the new study projects that microalgal fuels from algae grown only where water could be used efficiently would require a third as much land. In this scenario, the production of microalgal fuels would only make up for 17 percent of transportation petroleum imports, but it would still be enough to meet the total advanced biofuels goal set out by the Energy Independence and Security Act for the year 2022. Under those circumstances, fuel production would also require about a quarter as much water—that is, 350 liters (93 gallons) of water per liter of oil—as the maximum-production scenario.

“We looked at areas that required the least amount of water use,” says André Coleman, one of the co-authors on the study and a senior research scientist at the Pacific Northwest National Laboratory in Richland, Washington. “These areas are generally pretty sunny, but also have a high level of humidity.”

Based on those conditions, Coleman says that the Southeastern seaboard and the Gulf Coast hold the perfect climes for growing algae.

According to a PNNL press release, Mark Wigmosta, leader of the study and a chief scientist at PNNL, and his colleagues investigated the above scenarios by putting together an extraordinarily detailed nationwide database of characteristics of available land, with information at 30 meter (100 feet) spacing. They also compiled a 30-year meteorology record, and used it, the database, and a mathematical model of algal growth under various conditions, to evaluate potential productivity. The team published its findings April 13 in Water Resources Research, an AGU journal.

In subsequent coverage of the biofuel study, LiveScience.com noted that the water-conscious scenario would require “an area roughly the size of South Carolina.” By contrast, noted MSNBC’s CosmicLog blog, the maximum production scenario calls for a whopping “5.5 percent of the land in the lower 48 states.”

Thirsty as it is, algae offers advantages over other energy crops in that it doesn’t have to be produced with freshwater or compete with food production like many ethanol fuels, the researchers say. The fuels can be grown using waste water from sewage treatment ponds, the water leftover from oil and gas production or even salt water.

Coleman says that small companies have been working with Boeing and the Navy to produce algae fuels and now some of the major oil companies are starting to take an interest as well. BP, Exxon, Chevron, and Valero are also working on developing biofuels from algae. Last fall, Pike Research released a report that said the algae biofuels market could have a market value of $1.3 billion by 2020 on the path the U.S. is currently on.

– Eric Betz, contributing science writer.

GeoSpace is a blog on Earth and space science, managed by AGU’s Public Information staff. The blog features posts by AGU writers and guest contributors on all sorts of relevant science topics, but with a focus on new research and geo and space sciences-related stories that are currently in the news.

GeoSpace is a blog on Earth and space science, managed by AGU’s Public Information staff. The blog features posts by AGU writers and guest contributors on all sorts of relevant science topics, but with a focus on new research and geo and space sciences-related stories that are currently in the news.

Another viable source is through municipal garbage.

A few years back, a company performed a trial run that converted municipal garbage, to include plastics and food waste, into light, sweet crude oil via a high temperature/pressure steam process that they patented.

Every federal development dollar for alternative energy streams went instead to biodiesel. :/