12 September 2022

The 11 September 2022 Jagersfontein tailings dam failure

Posted by Dave Petley

The 11 September 2022 Jagersfontein tailings dam failure

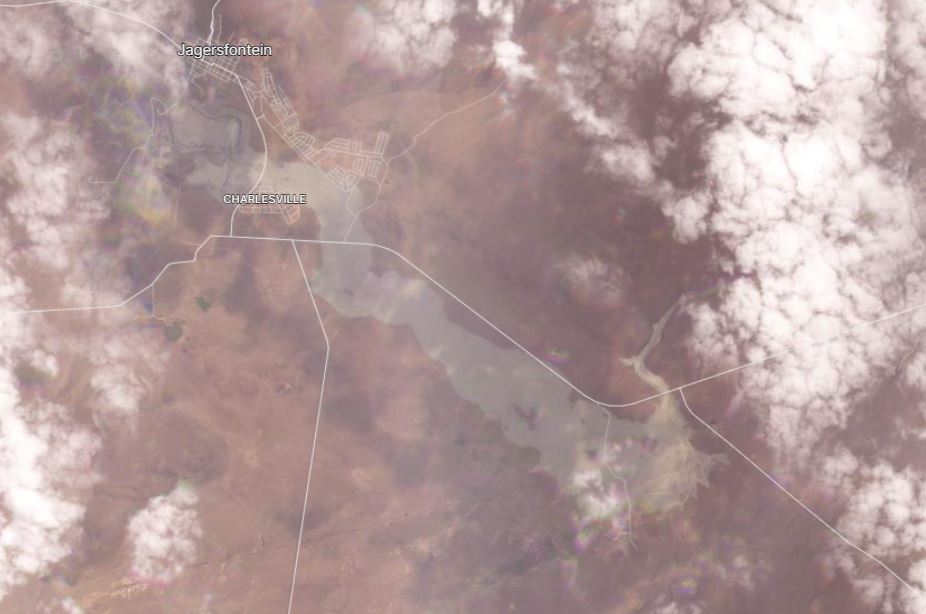

On 11 Seeptember 2022 a catastophic tailings dam failure occurred at the Jagersfontein diamond mine in South Africa. The location of the tailings facility is 29.772, 25.430. This is a Google Earth image of the site:-

Google Earth image of the Jagersfontein site, including the tailings facility that failed in September 2022.

.

The Jagersfontein diamond mine is closed. Bloomberg has reported that the facility is still owned by De Beers, although there is a remarkable lack of clarity:-

The mine’s dumps and slime still “belong” to De Beers and the government’s access has been restricted by a court order, [Nathi] Shabangu [a spokesman the Department of Mineral Resources and Energy] said. “We also have reports that the mine has been sold to other parties, without the involvement of the DMRE as per the court order,” he said.

There are some videos online showing the collapse of the tailings facility, of which is is perhaps the most remarkable:-

Residents of the mining town of Jagersfontein in the Free State are being evacuated after the mine dam burst at around 06:00 on Sunday, 11 September 2022 causing flooding in parts of the town. pic.twitter.com/5p6iTuWin6

— MDN NEWS (@MDNnewss) September 11, 2022

.

Reports indicate that at least three people have been killed and about 40 people have been hospitalised by the failure.

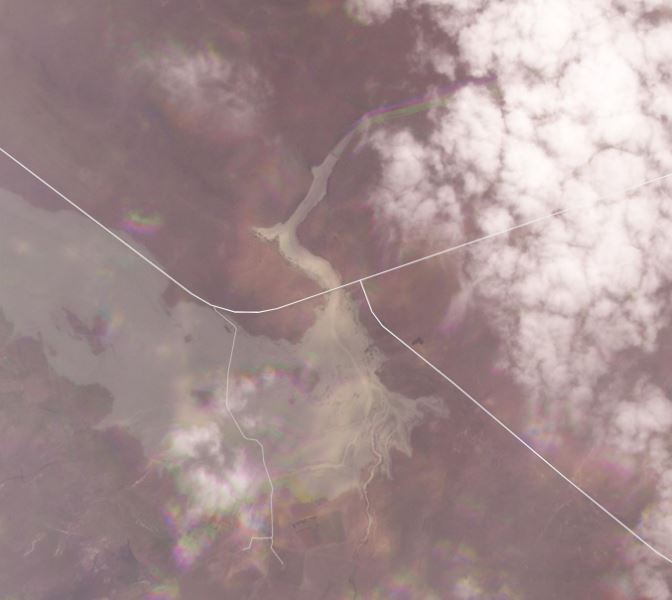

Planet Labs captured an image of the aftermath of the failure using their lower resolution PlanetScope instrument. Unfortunately, and unusually for this area, the image is slightly cloudy but the scale of the failure is clear enough:-

Satellite image showing the aftermath of the 11 September 2022 Jagersfontein tailings dam failure in South Africa. Image copyright Planet Labs, used with permission.

.

The plume of tailings extends about 8.5 km towards the southeast. It is up to about 1.5 km wide.

The image below shows the aftermath of the disaster in the area of the tailings facility itself:-

Satellite image showing the aftermath of the 11 September 2022 Jagersfontein tailings dam failure in South Africa. This image shows the failed tailings facility and inundation of local communities. Image copyright Planet Labs, used with permission.

.

The image shows a large breach in the southern wall of the facility. It appears that the pond, which is about 1 km long and 500 m wide, has largely emptied. Many houses downstream of the facility have been inundated.

Worryingly, the satellite images also indicate that the tailings have entered the main channel. Frustratingly, this area was covered in cloud at the time of the image collection:-

Satellite image showing the aftermath of the 11 September 2022 Jagersfontein tailings dam failure in South Africa. This image shows the tailings entering the main channel. Image copyright Planet Labs, used with permission.

.

The main channel flows out towards the north, with a small dam creating a lake. The image above shows the the dam has been overcome, although it is possible that it has retained a substantial volume of the waste. We will need to wait for better imagery to understand the impact better.

Once again, a major tailings failure has caused loss of life and severe environmental damage. This event, in a facility in which mining has ceased, will further raise questions about the long term stewardship of these facilities.

.

Acknowledgement

Planet Team (2022). Planet Application Program Interface: In Space for Life on Earth. San Francisco, CA. https://www.planet.com/

Dave Petley is the Vice-Chancellor of the University of Hull in the United Kingdom. His blog provides commentary and analysis of landslide events occurring worldwide, including the landslides themselves, latest research, and conferences and meetings.

Dave Petley is the Vice-Chancellor of the University of Hull in the United Kingdom. His blog provides commentary and analysis of landslide events occurring worldwide, including the landslides themselves, latest research, and conferences and meetings.

This youtube SABC news report shows the breach at 0:45, 1:16, 1:39 https://www.youtube.com/watch?v=7rG77n0V38U

Superb images————-Much appreciated. Spent months since 1977 collecting deep Earth mantle xenoliths from this famous diamond mine.

With thanks, best regards, Steve Haggerty.

#TSF #TRAGEDY #AGAIN — After unusual period and amounts of Precipitation March through August …..

See weather data here: https://www.linkedin.com/posts/ismetzger_jagersfontein-precipitation-tiri-activity-6975153421028913152-vEHR?utm_source=share&utm_medium=member_desktop

I posted a few items on LI — we have ready solutions with our Tailings and Impoundments reflectance Index Service. Built for exactly this scenario — a s apart of MANAGING the Asset. Which mines just do not want to do — aside from a few major operations …

More info on TIRI (Tailings and Impoundments Reflectance Index) here http://www.aamonitoring.net

As indicated in the post, there is lots of uncertainty regarding the current owner of the facility, however mining does not appear to have ceased after the De Beers sale in 2010. In Google Earth, you can see the size of TSF roughly doubles in areal footprint between 2010 to 2017. From 2017 until 2021, the pond volume is also substantially increasing. The large pond and associated saturation in the tailings likely played a role in initiating the failure and subsequent large runout and impact, but it seems unlikely that operations were ceased as described in this post. Regardless, the failure still raises questions about stewardship of the tailings at this site.

Big standing waves in that outflow. Makes me wonder if the dewatering system was working if it existed at all.

Just a question.

What is the grind for diamond process, from my understanding they do not grind fine so what might have caused the water to stay in the pond for that long?

And another note: if you go back in time using Google Earth Pro’s “wayback tool” (along the top of the screen), it looks to me that the site of the recent failure coincides with the site of a topographic bulge in the dam face and flatter ground beyond that grows over time. At least one access road was rerouted to accommodate this ground movement. I note the bulge was not there in the 2010 photos.

My money is on 1) a progressive bulge/failure in the dam face that the owners tried to buttress; or 2) a progressive rotational failure involving “native” material and the dam embankment. Could be a bearing failure in native with the slide surface daylighting out on the flat. Driving force would be the dam structure and impounded slurry.

The Jagersfontein tailings dam failure has occurred on the return water dam side of the dam. From Google Satellite images one can see extensive buttressing has been undertaking on the side where the failure occurred. What is also obvious from the satellite image is frequent overtopping of the day walls was the order of the day, which is indicative of the fact that no freeboard was maintained. South African law requires tailings facilities to maintain a minimum freeboard of 0.8m at all times.

Also from the image it is evident that the dewatering management was not functioning properly with both the top of the dam and the return water dam levels at maximum capacity. No toe drain paddocks are visible. it was just a matter of time before this disaster occurred.

Too much water…. Poor controls…my understanding is that de beers sold this to a private entity some 10 years ago. Governance is likely to be the issue. Tailings dams were always at the bottom of the priority list until the hazard became a risk to the primary objective ……EBITDAR $$ – Hubris remains prevalent and is a natural result of ignorance at board level.. I am sorry for those impacted – as usual, those with most to loose..

I processed the Sentinel-1 SAR data for the year prior to the collapse. There’s no shortage of noise and the resolution of S1 is not ideal, but there are clear accelerations in the InSAR results that would have been reported if they’d had InSAR monitoring.

The high water content on the tailings was unexpeceted. This remining project was planned ( and financed) on the assumption of thickening the fines from remining 24 Mt of coarse open stacked tailings; thickening them to and average particle size of 1.8 mm then depositing in the dangerously unstable old De Beers it. SRK supported that plan as the best strategy for stabilizing the pit and the most sensible and economical means of tailings waste disposal. They were denied pit deposition on the basis of its world heitage status as the largest hand dig pit in the world.

It has just come to my attention that Andrew Viettii, an expert f clays and their behavior in thickening, said the high water content is due to he particular nature of the Jagersfontein clays which differ from the the other remining project on which this one was modeled. The rewetted thickened tailings were supposed to settle out of solution and the clear water recycled back to processing. The addition of a specific chemical solution would have made that possible but the on site engineers were not aware of that. That made for a very liquid deposition of clays that remained in suspension and presumably could not be used in that state as process water. The perpetual wetness is inherently incompatible with an upstream construction type requiring a buttress that gave way in two locations out of the 4 break points. The InSAR done for WMTF by Value.Space support the commenter who opined on a bulge failure. The cumulative displacements through that section at the foundation were over 500mm over the two years pre failure in that area.